ASSEMBLY, IntEgration & testing

The assembly, integration & test (AIT) phase is essential. It comprises the assembly of components before the optical system is aligned, tested and qualified.

Integration is the penultimate moment in any project, entailing the assembly of all components prior to aligning, testing and qualifying the system. At Bertin Winlight, we deploy the resources needed to handle large instruments, check their dimensions and test optical and functional characteristics.

Our AIT department is mainly responsible for:

- Assembly, integration and testing of optical systems

- Environmental qualification of systems

- Packing and delivering optical systems

- System installation on site

- Maintenance and calibration

ASSEMBLY, INTEGRATION

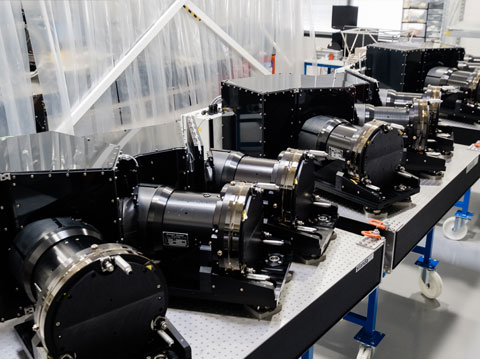

The integration team is in charge of assembling opto-mechanical systems and subsystems, as well as performing metal-metal and glass-metal bonding operations.

They also take charge of alignment and testing, to make sure that the system meets all customer specifications, especially for optical quality and interfaces.

Depending on customer needs, this team also takes charge of operating special tools, integrating command-control functions and wiring the motors needed to operate the system.

The department is also in charge of packing the system, to ensure trouble-free shipping to our customers.

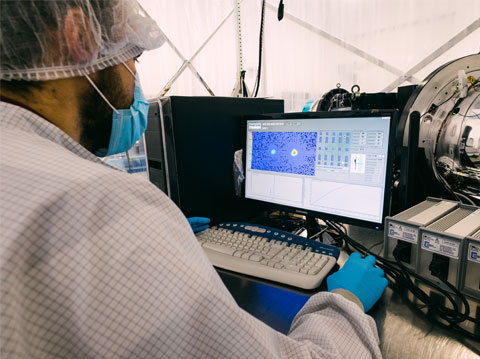

CLEAN ROOMS

Bertin Winlight has about 1,000 square meters of controlled-atmosphere assembly areas. These areas limit the concentration of dust particles (up to Class IS0 5 for space projects in particular), enabling us to assemble and test systems under optimized cleanliness conditions.

Separated from the production areas, the integration building is designed and built to offer a high degree of stability, and thus guarantee the accuracy of optical measurements.

TESTING & QUALIFICATION

Each system undergoes an internal acceptance test, possibly followed by a customer acceptance test in the plant. All specifications are checked using standard instruments or special test benches. Bertin Winlight naturally deploys a full range of test instruments and systems (theodolites, self-collimating viewfinder, MMT, 3D arms and measurement column, image spot measurement bench, collimators and interferometers), along with extensive environmental qualification systems:

- Environmental chambers

- Shaker

- Oven

- Cryogenic chamber

- Outgassing systems

All of this equipment is used to guarantee system quality and design life, and ensure the success of our customers’ projects.